Our technical papers provide in-depth insights into numerous challenges of today’s applications, technologies and processes and introduce you to proven solutions by Finetech.

IR Sensor Bonding

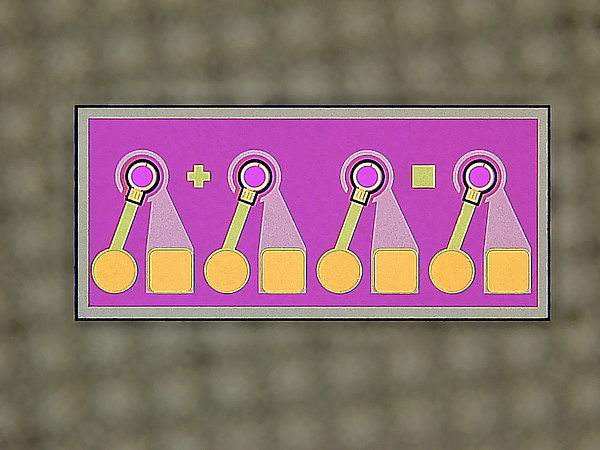

The preferred way of hybridization to produce large format, high density infrared (IR) thermal imaging sensors according to industry requirements is by using fine pitch micro Indium bump array interconnect bonding. However, there are specific challenges associated with Indium bump-to-bump die bonding.

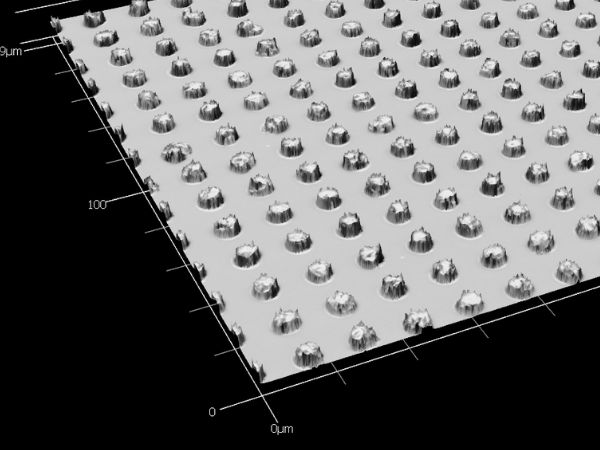

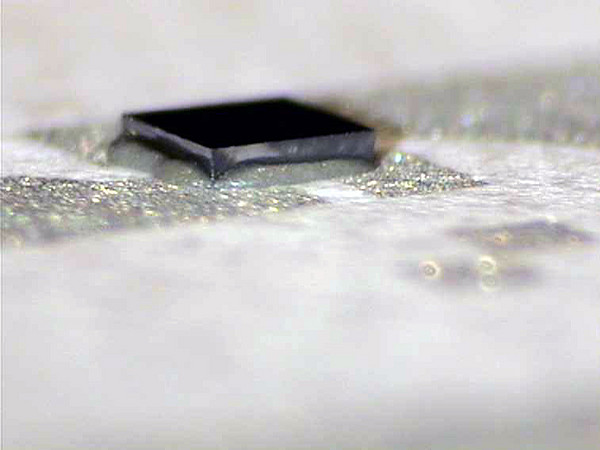

Indium Bump Interconnect (IBI) Flip Chip Bonding

Higher pixel / Qubit count and interconnect density on larger and larger chips is driving hybridization and monolithic integration. This results in increased demand for fine pitch micro Indium Bump Interconnect (IBI) flip chip die bonding solutions.

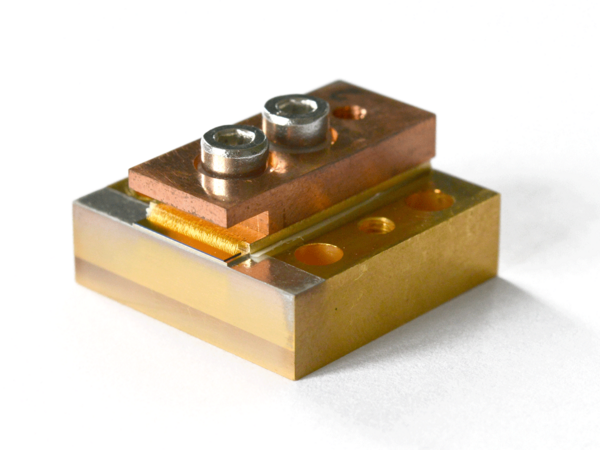

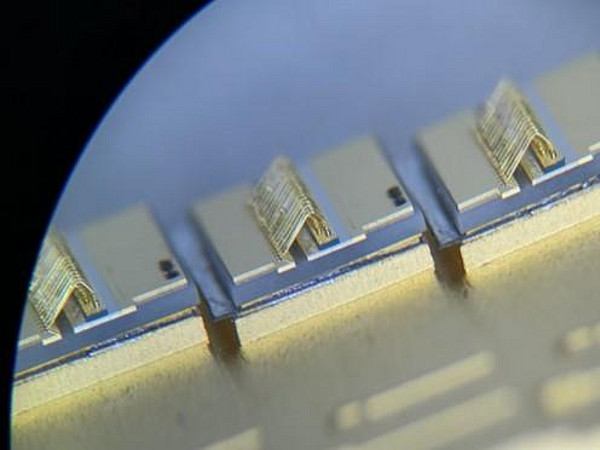

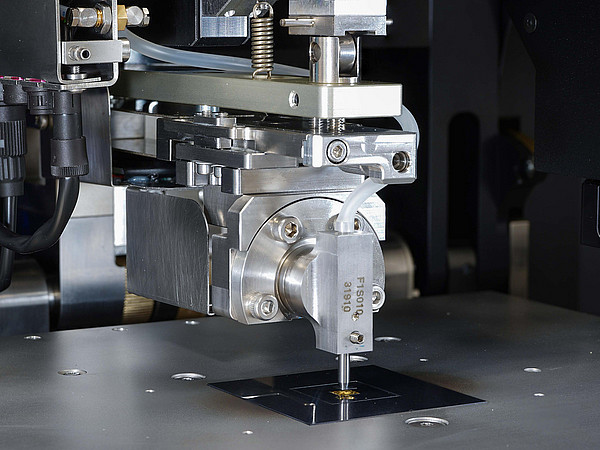

Automated High Power Laser Diode Assembly

High power laser diode assembly is a mass production process. An automated laser diode bonder is expected to output complete assemblies at a high unit/hour rate, while maintaining high accuracy and high repeatability for maximum yield over a large variation in component size, and type.

Prototype-to-Production

Finetech's "Prototype-to-Production" approach enables fast, creative and flexible product development and seamless process transfer from R&D to production, saving you time and minimizing technological and financial risks.

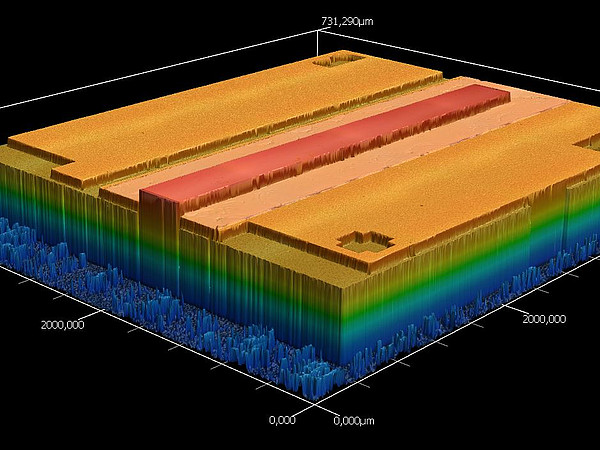

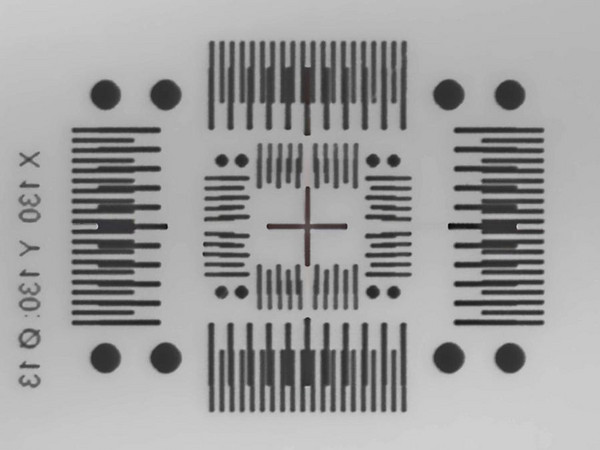

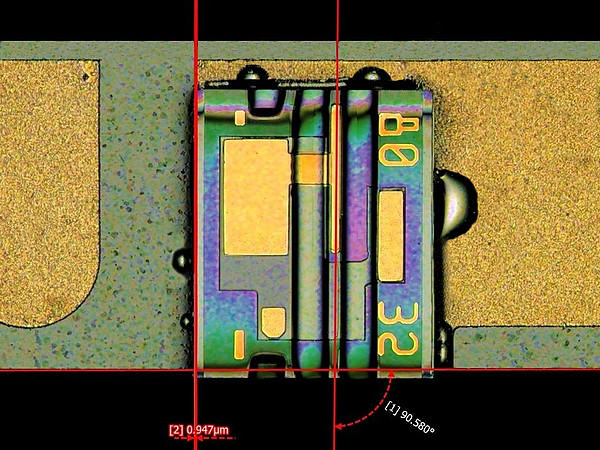

How we understand accuracy

This paper provides a transparent and verifiable method description of how the accuracy of Finetech placement and assembly systems is measured and specified.

Laser Bar Bonding

Semiconductor Laser diode bars are high power products, used in places where small and efficient emitting light sources are needed. Primarily, these Lasers are being used as pumping sources for optical resonators of solid state Lasers or gas Lasers.

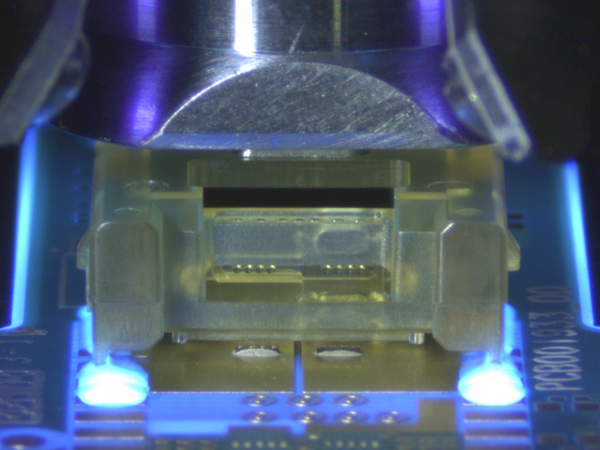

Optical Package Assembly

Optical packages are assemblies comprising optical and electronic components. Applications can be found e.g. in communication technologies where optical signals are transformed into electrical signals and vice versa.

VCSEL Assembly

The packaging of opto-electronic units is one of the key applications of Micro Assembly. Highly dense packaged multiplex transmitters, receivers and combined assemblies are...

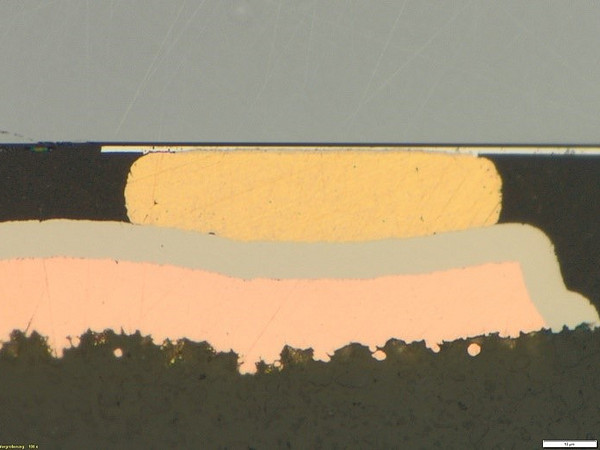

Eutectic Bonding with Au/Sn

Eutectic Gold/Tin (Au/Sn) is a hard solder alloy often used to bond demanding microelectronic and optoelectronic devices. They are available in different forms, such as pre-forms, solder paste or ribbons.

Multi Emitter Module Assembly

In order to reduce second-level packaging costs for optoelectronics manufacturing, Finetech has evaluated and is now offering an automatic solution for the packaging of CoS onto a heat sink via reactive multilayer systems (RMS).

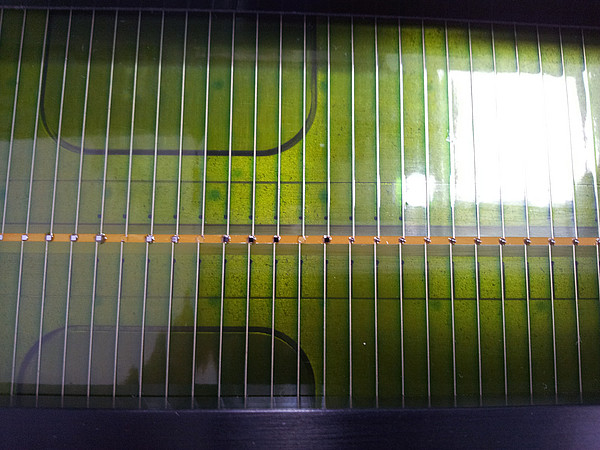

Bonding with Anisotropic Adhesive

In modern displays, Flex-on-glass and Chip-on-Glass are preferred bonding technologies. This goes along with using anisotropic conductive foils or pastes which have a fundamentally different functional principle compared to common adhesives or solder materials.

Laser Assisted Die Bonding

Finetech's laser-assisted bonding technology is used in C2S and C2W applications with high demands regarding speed, highest accuracy and localized heat input.

Thermocompression Bonding

Thermocompression bonding is a quick and easy method to reliably connect flip-chips. As the name suggests, this connecting method relies on force and temperature.

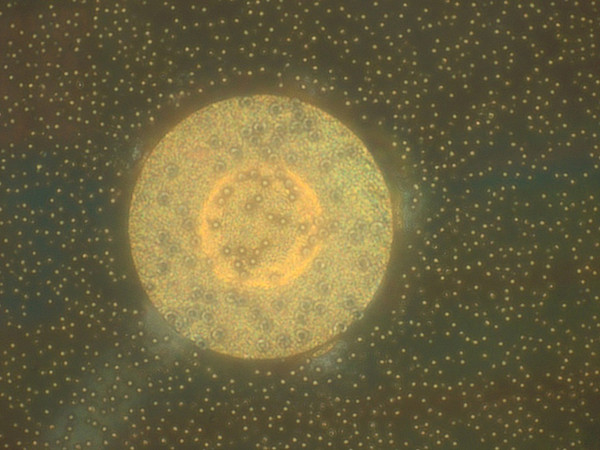

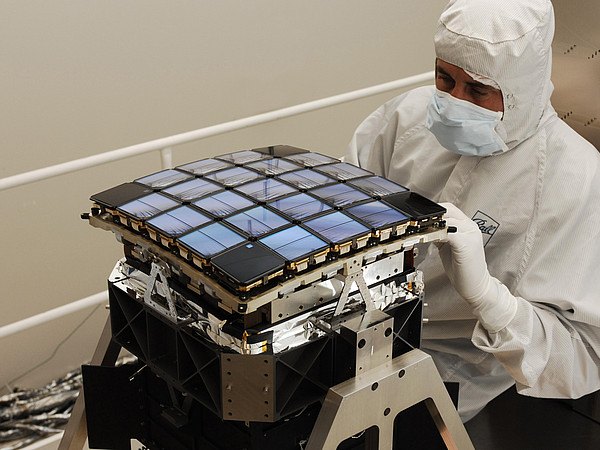

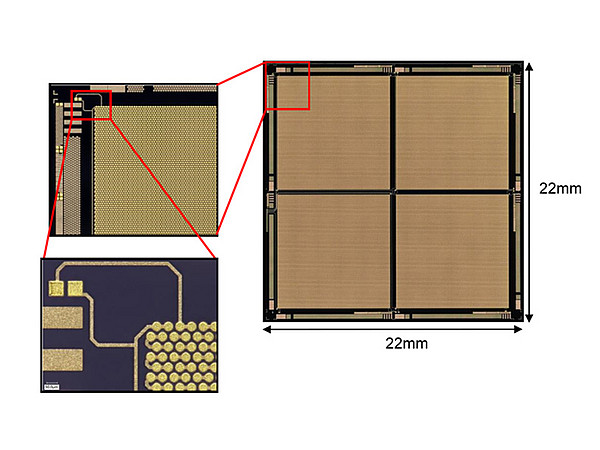

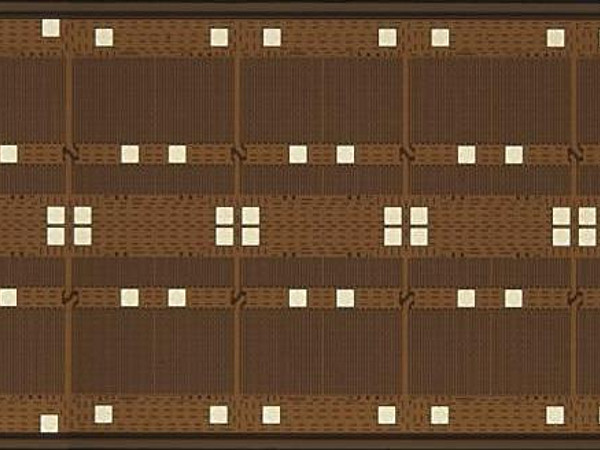

Focal Plane Array (FPA)

A Focal Plane Array (FPA) is a sensor with a two-dimensional detector pixel matrix, i.e. for infra-red light or X-rays, positioned in the focal plane of an optical system.

RFID Assembly

RFID chips (Radio Frequency Identification) are increasingly used in industrial and consumer products. They come in sizes from several millimeters down to a few microns, with very thin and flexible substrates prone to thermal stress.

Adhesive Technologies

Between two bond partners, adhesive materials can be applied in various ways: dispensing, stencil printing, pin transfer or as a film working as an intermediate connection.

Ultrasonic Die Bonding

Ultrasonic / thermosonic bonding is a process primarily used for bond wires but also for flip chip bonding. Ultrasonic allows to generate a mechanically and electrically stable connection.

Bonding Technologies for 3D Integration

An overview about different interconnects used during the system evaluation of the FINEPLACER® sigma

Flip-chip Bonding to Organic Substrates

Standard IC packages with an increased number of I/O pads suffer from larger volume, increased cost, increased wire bonding resistances and parasitic inductances while offering...

Copyright © 2024 Finetech GmbH & Co. KG, All rights reserved.