By using this element, you agree that your data will be transmitted to external services (https://www.youtube-nocookie.com) and that you have read our privacy policy.

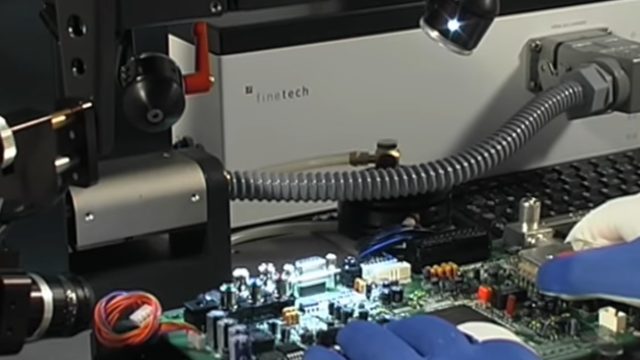

BGA Rework

Desoldering, soldering, residual solder removal on flat panel TV PCB.

By using this element, you agree that your data will be transmitted to external services (https://www.youtube-nocookie.com) and that you have read our privacy policy.

CSP Rework on Mobile Phones

By using this element, you agree that your data will be transmitted to external services (https://www.youtube-nocookie.com) and that you have read our privacy policy.

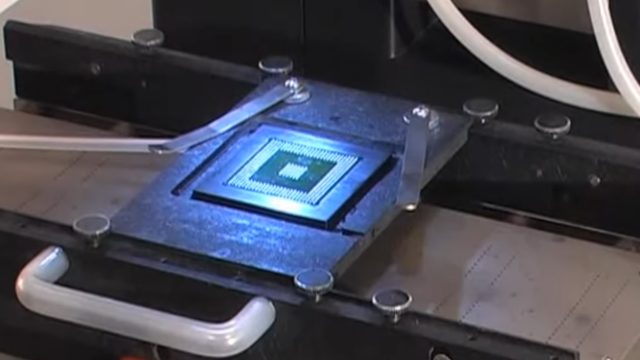

BGA Reballing

By using this element, you agree that your data will be transmitted to external services (https://www.youtube-nocookie.com) and that you have read our privacy policy.

Rework of GPU

Typical process steps of CPU/GPU rework. This includes pre-inspection, board preparation, profiling de-soldering the component, residual solder removal, reballing, special processes such as solder paste printing or dispensing, soldering the new/reworked component and finally the follow-up optical inspection.

By using this element, you agree that your data will be transmitted to external services (https://www.youtube-nocookie.com) and that you have read our privacy policy.

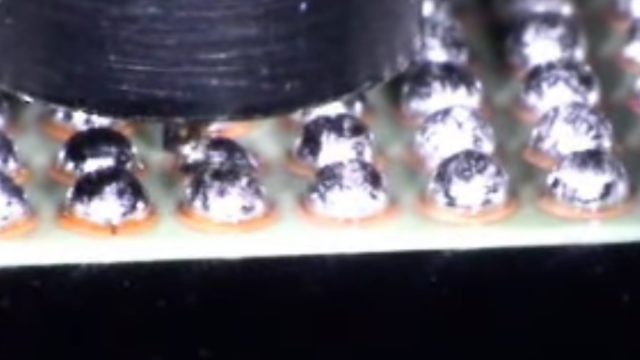

Contactless Residual Solder Removal

Contactless solder removal (site dressing) showing alignment of tool and component, application of flux and the removal process.

By using this element, you agree that your data will be transmitted to external services (https://www.youtube-nocookie.com) and that you have read our privacy policy.

01005 Small Passives Rework

Process camera video: desoldering of 01005 small passive with small gap.

By using this element, you agree that your data will be transmitted to external services (https://www.youtube-nocookie.com) and that you have read our privacy policy.

Single Ball Reballing

Process camera video: removing a solder ball bridge in a BGA

By using this element, you agree that your data will be transmitted to external services (https://www.youtube-nocookie.com) and that you have read our privacy policy.

QFN desoldering

Process camera video: removing a QFN component.

By using this element, you agree that your data will be transmitted to external services (https://www.youtube-nocookie.com) and that you have read our privacy policy.

PoP Rework

Process camera video: Active clamping soldering head for rework of PoP stacked components.

By using this element, you agree that your data will be transmitted to external services (https://www.youtube-nocookie.com) and that you have read our privacy policy.

QFN Rework

Direct Component Printing of QFN or MLF. No additional reflow process for solder transfer onto the component necessary. Minimum heat load to component. QFN rework in OEM quality!

By using this element, you agree that your data will be transmitted to external services (https://www.youtube-nocookie.com) and that you have read our privacy policy.

µBGA Desoldering

Process camera video: Desoldering a µBGA component.