Author: Dan Lilie

Abstract: The rework of BGA components with large ball arrays, processor units (CPU) as well as graphics chips (GPU) and CSP with a fine pitch array demand special device configurations that combine precise thermal management with high placement accuracy and high-resolution optics to ensure rework processes with void-free solder joints and accurate alignment. The demand for more functionalities and performance on smaller PCB continues the trend of miniaturized, increasingly complex devices with extreme packing density and a rising I/O count.

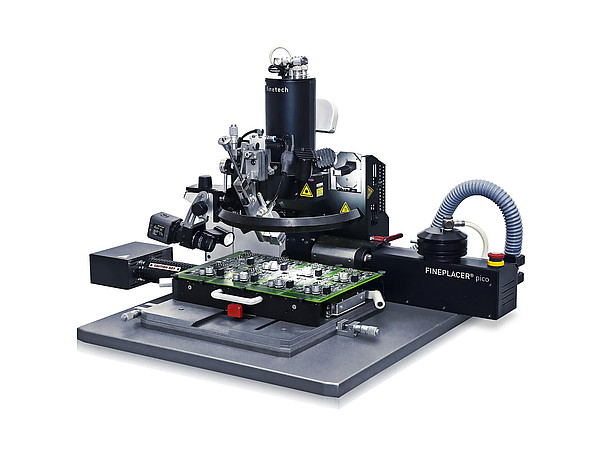

Frequently, BGA rework is used as a synonym for SMD rework. Therefore, many information in this document are not only valid for array packages but SMD rework in general, showing rework strategies for such components and approved Finetech solutions.